COURSES

Choose a course that best suits your needs, or to improve your skills and elevate your future in the welding industry.

All hands-on Training.

Training for pipe and structural welding.

Real-world training simulators. (coming soon)

Scaffold, confined, restriction and pipeline welding.

Safety training and hazard awareness.

No body gets hurt. Safety is our #1 priority.

COURSE OPTIONS

TIG & STICK

TIG, MIG & FLUX

STICK, MIG & FLUX

PIPELINE WELDING

SIMULATOR UNDE-CONSTRUCTION

STRUCTURE WELDING

PLANT WELDING

ENHANCE YOUR SKILLS

Improve Quality & Productivity

1 ON 1 TRAINING

- 4HR CLASS

- SHARPEN ANY SKILL

- LIMITED SPOTS ONLY

- CALL FOR AVAILABILITY

PIPE WELDING

- 4-5HR CLASS

- BEGINER→INTERMIDIATE

- SATURDAY CLASS

RESTRICTION

- 60HRS

- 4 WEEK COURSE

- DAY/NIGHT CLASS

TIG WELDING

(GTAW)

Gas tungsten arc welding, also known as tungsten inert gas welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas. It is one of the strong welds but difficult to master. Only an experienced welder can perform this art as they use both hands to perform the welding. The welding results are precise, strong, visually appealing, and require no cleanup. It is used to weld stainless steel, aluminum, magnesium, nickel, and copper with ease. The process is quite popular for industries that work on nonferrous metal as tubing, bicycles, and vehicle manufacturing. It is suitable to repair tools made from aluminum, magnesium, and stainless steel.

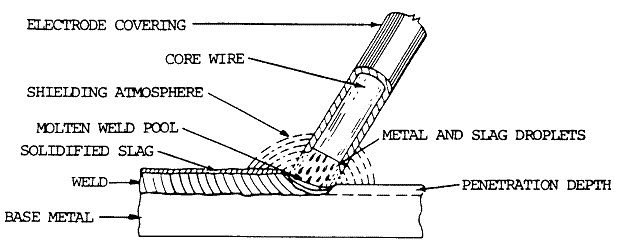

STICK WELDING

(SMAW)

Shielded metal arc welding,The filler material here is a replaceable stick electrode. It generates the arc when the end of the stick contacts the base metals. The heat of the arc melts the electrode’s filler metal to make the weld. It coats the stick electrode with a flux that creates a shielding cloud to protect the weld zone from oxidation. The flux on cooling changes into slag, which needs to chip off. these are century-old types of welding processess and improve regularly from time to time. It is popular welding because of its low cost, and easy and simple operability. The process comes with spatter welding that needs cleanup, essentially.

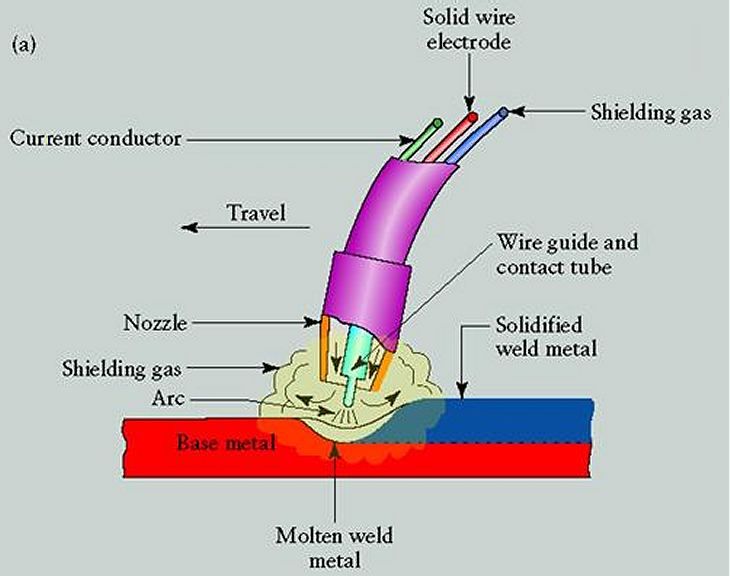

MIG WELDING

(GMAW)

MIG welding is a simple, popular form of welding, a novice can operate and master the art easily.

MIG stands for metal inert gas and sometimes may be called gas metal arc welding (GMAW). It is a semi-automatic, quick process where filler wire is fed through the gun, and shielding gas is expelled around to protect from environmental impurities. The filler wire is fed on a spool to act as an electrode as well.

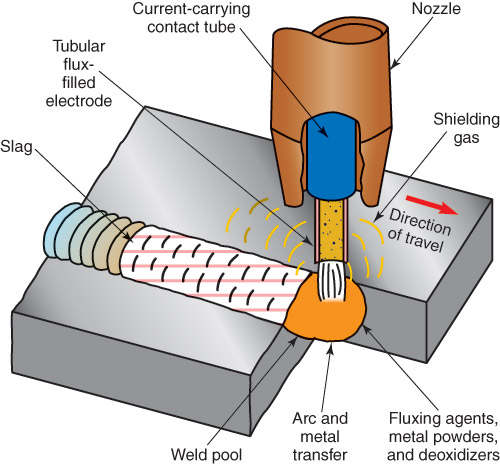

FLUX CORE WELDING

(FCAW)

FCAW is similar to MIG welding, as the power source can perform both types of welding. MIG welding needs filler wire working as an electrode fed continuously from the gun. Conversely, FCAW has a wire with its core as flux and creates a gas shielding zone around the weld. No need for any external shielding gas in this welding type. The process is versatile and works for thick metals. The welding process is efficient and works well for heavy metals with high-heat welding. No need for any external gas makes it a choice of welding at a lower cost. It is useful for thicker metal and is used in heavy equipment repair. Before you get a beautiful clean weld, you need to do cleanup from the slag of flux. It is done with ease outdoors as it does not require a shielding gas.

REQUEST A CALL BACK

Phone

(346)494-8322